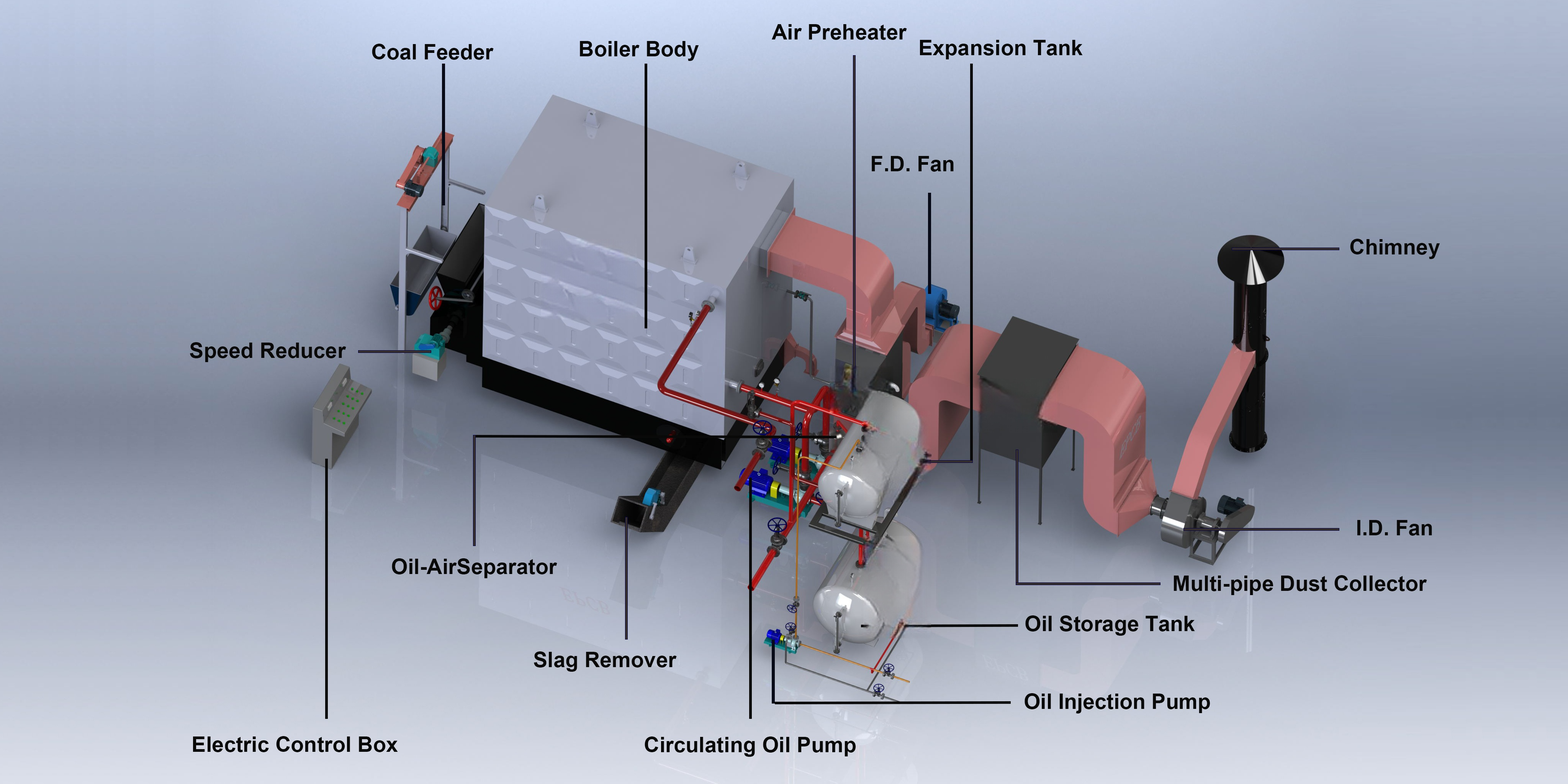

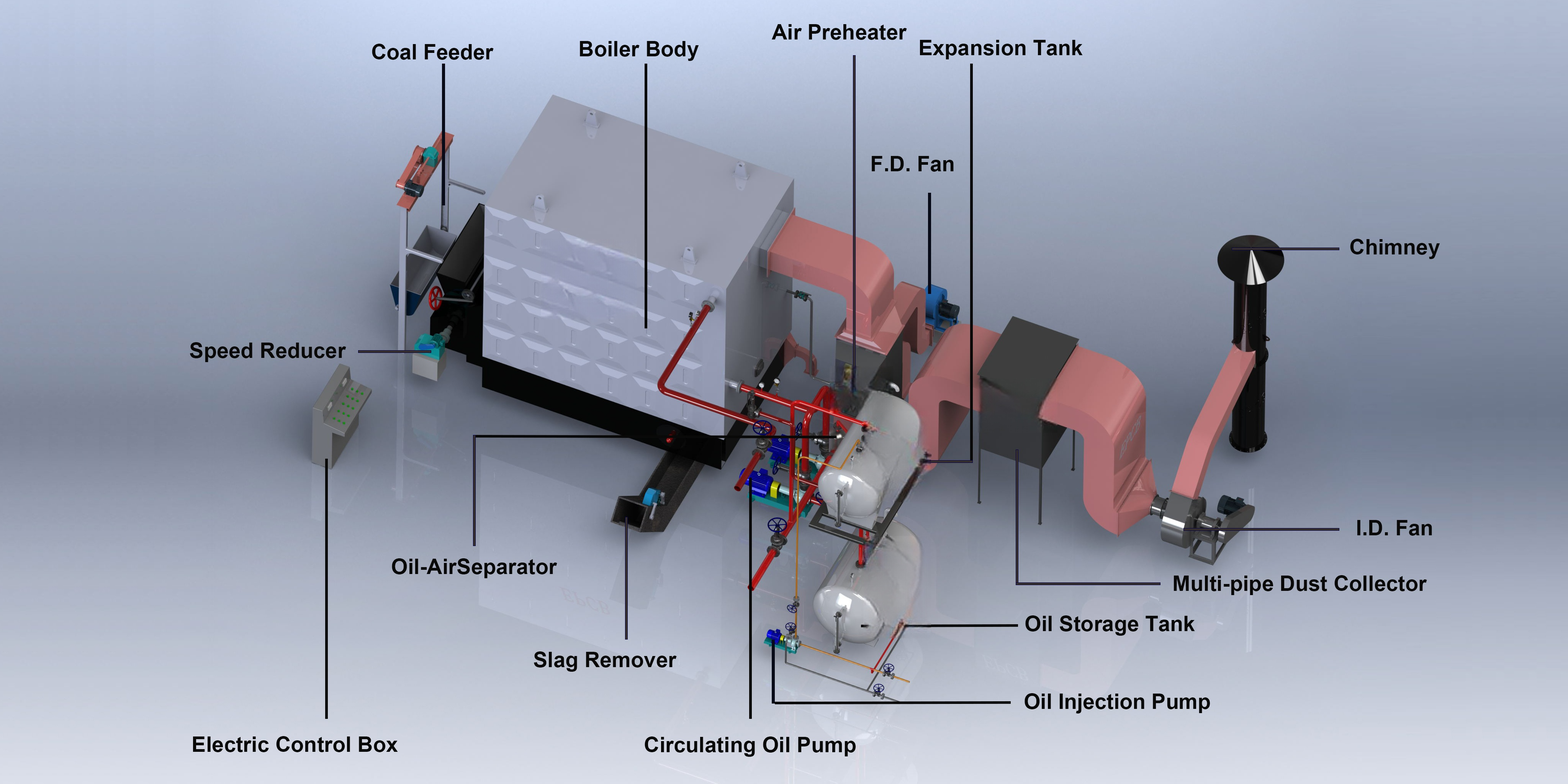

Product Description: YX Coal/Biomass Fired Thermal Oil Boiler

YX coal-fired and biomass thermal oil boilers represent high-performance, environmentally sustainable heating solutions designed for demanding industrial applications across chemical, textile, food processing, pharmaceutical, and other thermal-dependent sectors. Incorporating cutting-edge combustion technology, these systems achieve exceptional thermal efficiency exceeding 95%, significantly reducing fuel consumption and operational expenses.

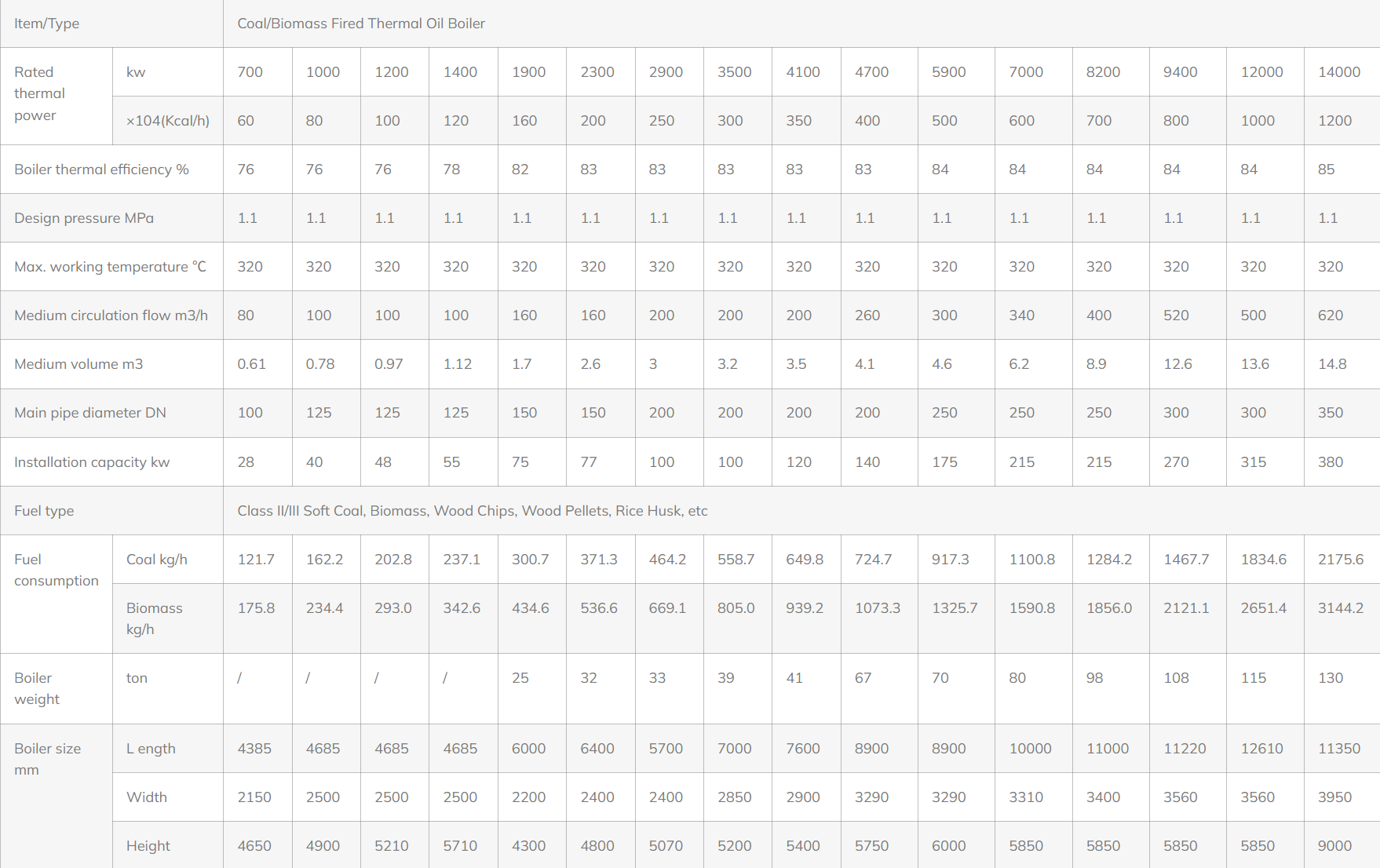

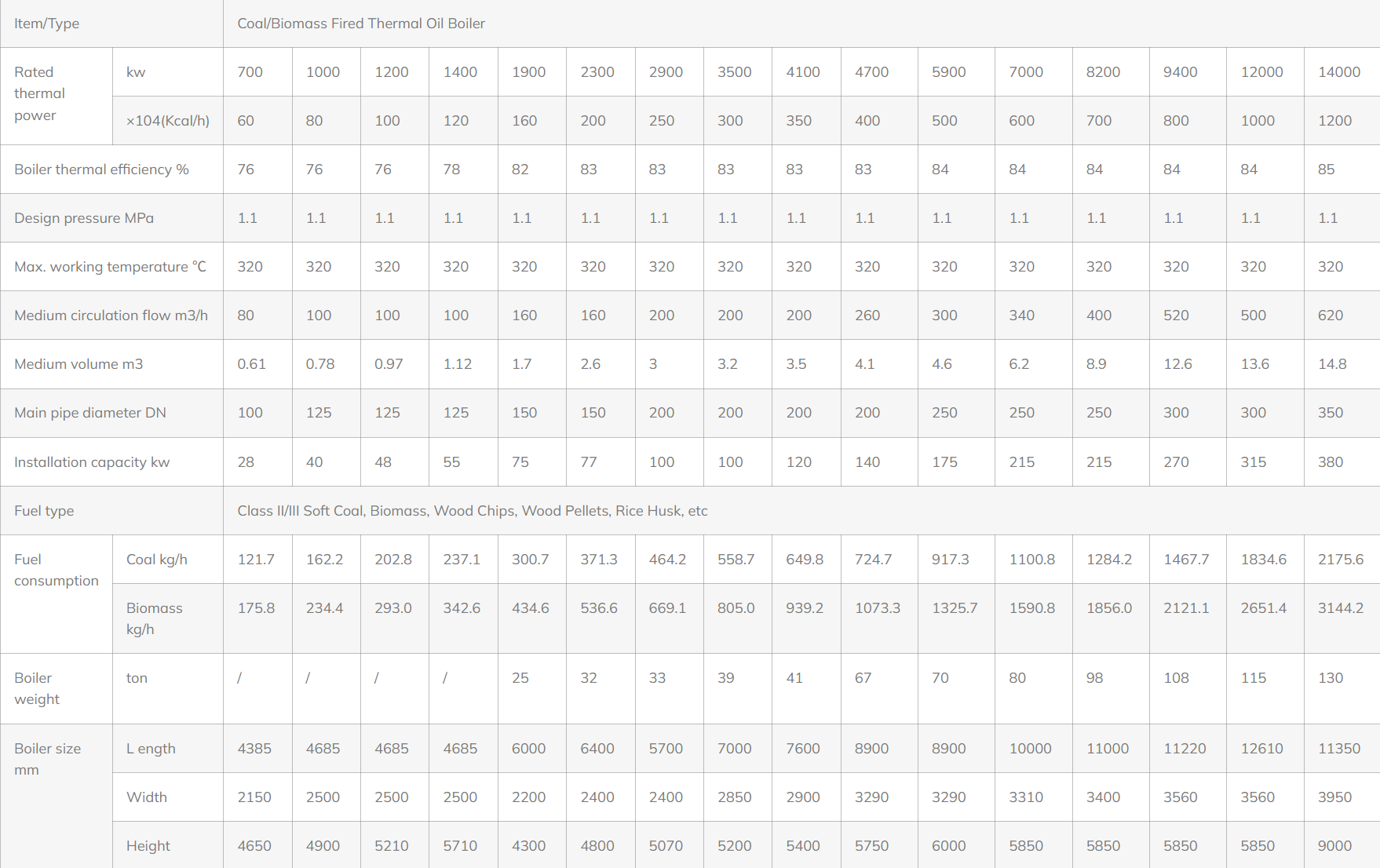

Coal/Biomass Thermal Oil Boiler Specifications

Coal/Biomass Fired Thermal Oil Boiler Features:

Exceptional Efficiency and Fuel Versatility

YX coal/biomass thermal oil boilers achieve remarkable combustion efficiency of ≥95%, substantially improving energy utilization while reducing fuel consumption. These systems are engineered to handle diverse fuel options including bituminous coal, anthracite, wood chips, wood pellets, and agricultural waste such as rice husks and corn stalks. This fuel adaptability guarantees smooth operation across various industrial sectors and geographical locations, optimizing both operational expenses and fuel sourcing flexibility.

Consistent High-Temperature Performance

YX boilers maintain a stable thermal output reaching 350°C, delivering precise and dependable performance for crucial industrial applications including drying processes, chemical synthesis, and sterilization operations. The sophisticated temperature management system ensures minimal variation, meeting the exacting thermal demands of textile, pharmaceutical, and food processing industries.

Environmentally Responsible Compliance

YX incorporates state-of-the-art combustion technology along with optional flue gas treatment systems featuring high-efficiency dust collectors and desulfurization equipment. These innovations substantially decrease emissions of CO₂, SO₂, and particulate matter, ensuring adherence to global environmental regulations. This approach allows businesses to sustain eco-friendly manufacturing processes while achieving their sustainability objectives.

Enhanced Safety and Operational Reliability

With safety as a fundamental design principle, YX boilers incorporate comprehensive protection systems including over-temperature safeguards, low oil level alerts, pressure monitoring, and emergency shutdown capabilities. These integrated safety measures ensure secure and stable operation, reducing potential hazards and maintaining uninterrupted production even in challenging operating conditions.

YX Oil Fired Steam Boiler Applications

YXBoiler gas fired steam boilers are widely used across various industries, including chemical, paper making, textile, food, pharmaceuticals, heating, and manufacturing processes. The versatility of YXBoiler gas fired steam boiler allows for the efficient generation of steam to meet the specific needs of each industry.