Rated Evaporation Capacity is 1 to 20 t/h Rated Pressure is 0.7~1.6MPa (7~16Bar) Design Efficiency is up to 81~82% Fuel: Biomass Pellet, Wood Chips, Sawdust, Palm Hulls, and more. Competitive Factory Price

Aix biomass steam boilers deliver sustainable, high-efficiency steam and hot water solutions using renewable biomass fuels like wood chips, pellets, and agricultural residues. Aix provides eco-friendly, ASME-compliant systems for industries such as paper, food, chemical, textile, and beverage production.

Aix biomass steam boilers, also known as biomass-fired steam boilers, generate steam by combusting renewable fuels such as wood chips, biomass pellets, sawdust, palm hulls, rice husks, sunflower seed hulls, and coconut hulls. Aix offers end-to-end solutions, including:

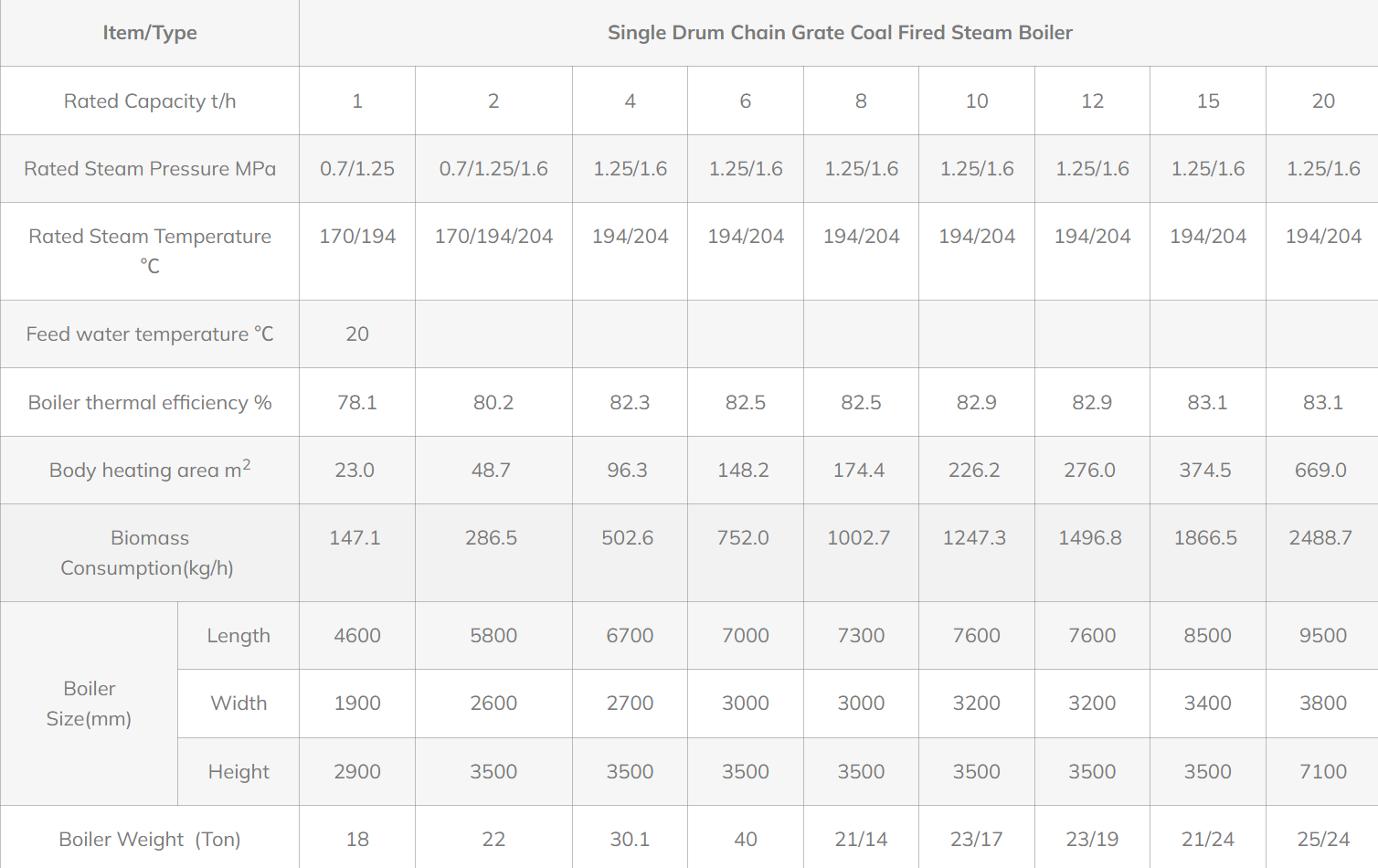

These boilers, with evaporation capacities of 1 to 20 tons per hour and pressures of 0.7 to 1.6 MPa (10 to 16 Bar), provide cost-effective, sustainable heating for commercial and industrial applications.

Aix biomass steam boilers are engineered for efficiency and durability, featuring:

The front-positioned furnace includes a rising flue duct, while the rear convection bank optimizes energy utilization, ensuring reliable and high-performance operation.

Aix boilers utilize a reciprocating grate design to streamline three core processes:

Post-combustion, an induced draft fan extracts cooled gases, which are filtered through a dust catcher to ensure cleaner emissions and compliance with environmental standards.

Specifications of EPCB Electric Steam Boiler

Aix leads the domestic and Asian markets. Key highlights include: